Butt Joint Machine

- Better Strength.

- Cost Effective.

- No Filler Material.

- Light Weight.

- Easy to Use.

Butt Joint Machine

- Less Time-Consuming.

- Cost-Effective.

- No Filler Material required.

- Better Tensile Strength

- Uniform Appearance.

butt joint machine

Butt Joint Machine

The Butt Joint machine is a top choice for welding TMT bars in India, offering advanced technology for construction projects. It’s designed for fast and efficient welding, needing only electric current and no extra materials like gas or electrodes. This machine is perfect for making lots of welded joints quickly, making it a great help for building and infrastructure work. It’s small, light, and easy to move around, which saves time and makes work easier. As a leading welding solution in India, this machine is a smart pick for anyone looking for quick and reliable TMT bar welding.

Economical benefits of Butt joint

- Simplicity: Butt joints are among the simplest and most straightforward joints to create. This simplicity translates into reduced labor and manufacturing costs.

- Reduced Material Waste: With a butt joint, there’s no overlapping or additional shaping required, which minimizes material waste and lowers costs.

- Less Skilled Labor: Because butt joints require fewer specialized skills and complex techniques, they can be completed with lower-skilled labor, reducing labor costs.

View the Video for a Deeper Understanding

Economical benefits of Butt joint

Technical benefits of Butt joint

Technical benefits of Butt joint

Technical benefits of Butt joint

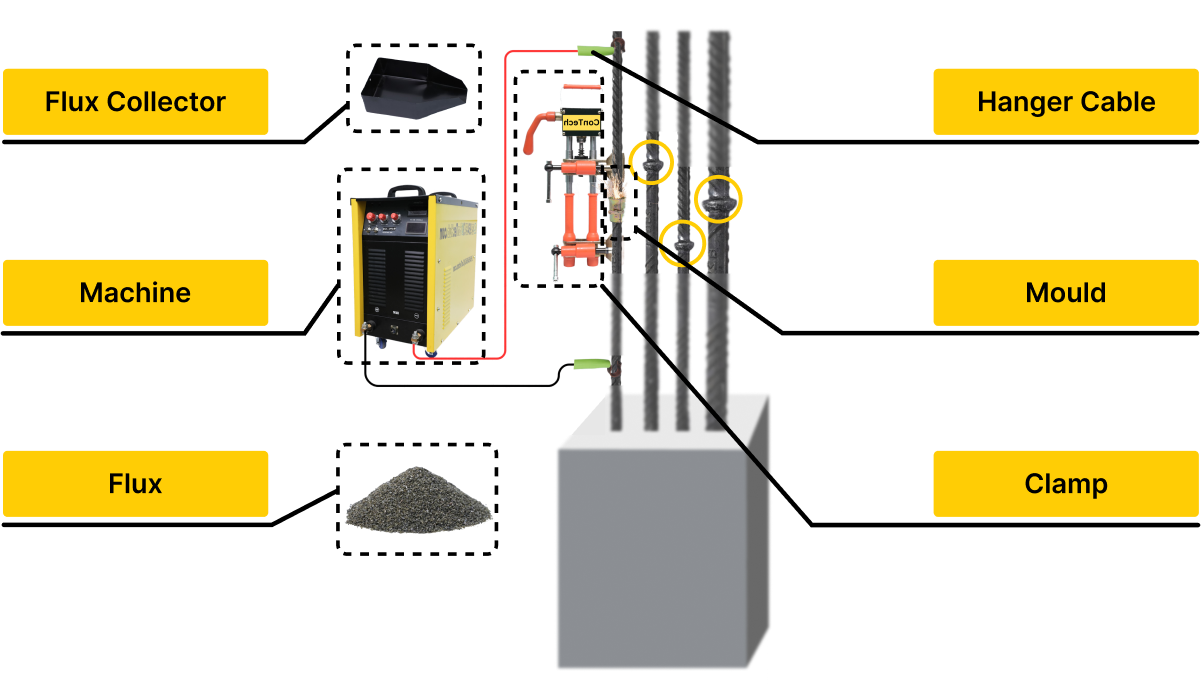

Component of Butt Joint Machine

Procedure

Learn how to use a butt joint machine in construction or column splicing engineering in our video. We demonstrate the process with this video. We also explain the preparation needed for a strong and seamless connection. Check now for step-by-step instructions.

Procedure

Learn how to use a butt joint machine in construction or column splicing engineering in our video. We demonstrate the process with this video. We also explain the preparation needed for a strong and seamless connection. Check now for step-by-step instructions.

We are committed to providing quality service to all of our clients

Customer review

Hear from our satisfied customers about their positive experience using butt joints in their projects. In our video, they share how butt joints provided a strong and seamless connection between materials, making their projects more durable and reliable.

Technical Benefits

Study the technical advantages of butt joints in construction or column splicing engineering. They provide strength, flexibility, and easy installation for seamless rebar connections. This video explains techniques and how to use butt joints.

Butt Joint Site installation

Learn how the Butt Joint method saves steel and makes RCC columns stronger. We’ll walk you through the whole process, from the first design steps to the final building stage, so you understand this ground breaking approach fully.

Why Butt Joint?

Enhanced Strength

It provides bar-break tensile strength comparable to rebar couplers, ensuring strong and reliable joints.

Standard Reference

Our solution meets all the strength criteria outlined in IS 9417:2018, ensuring that your construction project…

Cost Savings

Our technology eliminates the need of costly rebar overlapping, saving you money on materials and labor.

Common FAQ’s

Frequently Asked Questions

A Butt Joint Machine is not just any normal welding; it is specifically mentioned in IS code 9417:2018 as “Flash Butt joint” where no filler material is used to join TMT bars, unlike normal welding where filler material is used.

IS code 9417:2018 approves five types of welding methods for rebar joining, among which the Butt Joint method is considered the best. This is because in this method, there’s no need to cut the rebar at a specific angle; rather, two TMT rebars are melted edge to edge to join them.

The Butt Joint Machine utilizes a 90-volt DC current, providing a safe operating environment for everyone. It’s also important to adhere to all safety protocols without any negligence and understand their implementation.

Yes, our trainer will be available at your site to teach your laborers how to operate the machine and explain all the details. The trainer will continue to guide them until your laborers have properly learned how to use the machine.

Yes, the Indian standard code (IS 9417:2018) permits the Butt Joint Method, which passes both bend and tensile tests. We will provide Butt Joint test reports, or you can conduct the tests at any NABL certified laboratory.

Operating the Butt Joint Machine is not a complicated process, and we offer certified training. If you wish to undergo certified training, it is available at our institute in Jaipur or Ahmedabad.

Yes, Butt Joint can be used in infrastructure projects such as bridges, roads, dams, metros, as well as residential building projects like malls, hospitals, schools, and colleges.

एक बट जॉइंट मशीन केवल कोई सामान्य वेल्डिंग नहीं है; यह विशेष रूप से IS कोड 9417:2018 में “फ्लैश बट जॉइंट” के रूप में उल्लेख किया गया है, जहां टीएमटी बार को जोड़ने के लिए कोई भरकर सामग्री उपयोग नहीं होती, असमान सामग्री का उपयोग किया जाता है, जैसा कि सामान्य वेल्डिंग में किया जाता है।

आईएस कोड 9417:2018 में रीबार जोड़ने के लिए पाँच प्रकार की वेल्डिंग विधियों को मंजूरी दी गई है, जिनमें बट जॉइंट विधि को सर्वोत्तम माना जाता है। इसका कारण यह है कि इस विधि में, रीबार को एक विशिष्ट कोण पर काटने की कोई आवश्यकता नहीं है; बल्कि, दो टीएमटी रीबार को एक-दूसरे के किनारे मिलाकर मिलाया जाता है।

ओवरलैप की तुलना में, बट जॉइंट विधि का उपयोग करके आप अपने प्रोजेक्ट में लागत और समय दोनों बचा सकते हैं। बट जॉइंट विधि की लागत और तकनीकी लाभों के बारे में अधिक जानकारी हमारी वेबसाइट पर उपलब्ध है।

बट जॉइंट मशीन 90-वोल्ट डीसी धारा का उपयोग करती है, जो सभी के लिए एक सुरक्षित ऑपरेटिंग वातावरण प्रदान करती है। सभी सुरक्षा प्रोटोकॉल का पालन करना भी महत्वपूर्ण है बिना किसी लापरवाही के और उनके पालन को समझना भी।

हां, हमारे प्रशिक्षक आपकी साइट पर उपलब्ध होंगे ताकि आपके श्रमिकों को मशीन का उपयोग कैसे करना है और सभी विवरणों को समझाने के लिए। प्रशिक्षक उन्हें सही तरीके से मशीन का उपयोग सीखाने तक उन्हें गाइड करते रहेंगे।

हां, भारतीय मानक कोड (आईएस 9417:2018) बट जॉइंट मेथड की अनुमति देता है, जो कि बोधगम और टेंसाइल टेस्ट दोनों में पास होता है। हम बट जॉइंट टेस्ट रिपोर्ट प्रदान करेंगे, या आप किसी भी एनएबीएल प्रमाणित प्रयोगशाला में टेस्ट करा सकते हैं।

बट जॉइंट मशीन का ऑपरेट करना इतनी कठिन प्रक्रिया नहीं है, और हम प्रमाणित प्रशिक्षण भी प्रदान करते हैं। यदि आप प्रमाणित प्रशिक्षण लेना चाहते हैं, तो यह हमारे इंस्टीट्यूट में जयपुर या अहमदाबाद में उपलब्ध है।

हां, बट जॉइंट को पुरालेख प्रोजेक्ट्स जैसे कि पुल, सड़क, बांध, मेट्रो, साथ ही मॉल, अस्पताल, स्कूल, और कॉलेज जैसे निवासीय इमारत प्रोजेक्ट्स में उपयोग किया जा सकता है।